The water quenching process transforms inexpensive, low carbon steel into high-strength bars. This process involves immersing the bar’s surface layer in water, exerting pressure on the crystal structure of intermediary layers and deforming them. Concurrently, it tempers the quenched layers using heat derived from the bar’s core.

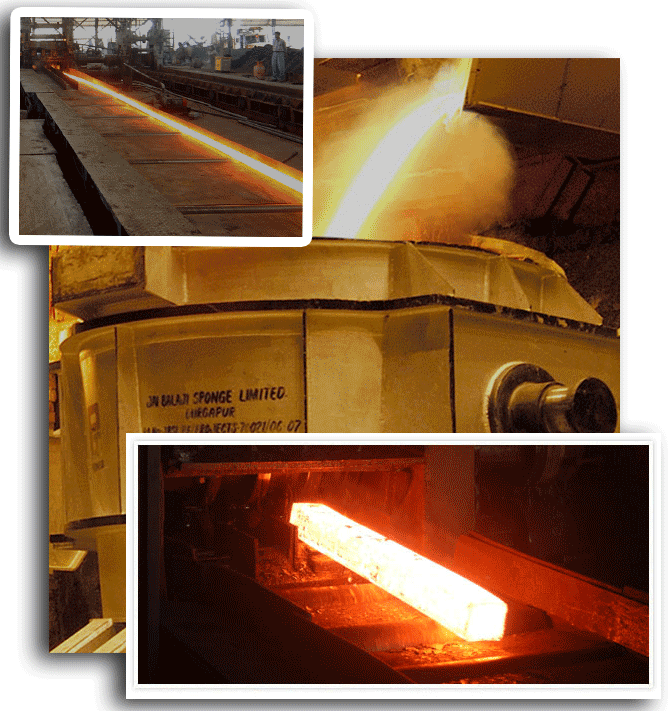

Steel billets, also referred to as “pencil ingots”, with a diameter of 130 mm, undergo heating to temperatures ranging from approximately 1200° C to 1250° C in a reheat furnace. Subsequently, they undergo progressive rolling to achieve the desired shape and size of the reinforcing bar. Following rolling, the billets pass through a quench box, where the surface layer undergoes conversion to martensite, inducing shrinkage. This shrinkage applies pressure on the core, facilitating the formation of correct crystal structures while retaining the core’s heat and austenite. A microprocessor is instrumental in maintaining temperature differentials across the bars’ cross-sections, ensuring consistent mechanical properties throughout the processes.

Upon exiting the quench box, the bar exhibits a temperature gradient across its cross-section. As the bar cools, heat migrates from the centre to the surface, enabling appropriate tempering of an intermediate ring of martensite and bainite by the bar’s heat and pressure.

Ultimately, the slow cooling post-quenching automatically tempers the austenitic core to ferrite and pearlite on the cooling bed.

These bars feature varying microstructures across their cross-sections, comprising robust, resilient, tempered martensite in the surface layer, an intermediate layer of martensite and bainite, and a refined, ductile core of ferrite and pearlite.

As a premier and renowned TMT bar manufacturer operating in West Bengal, we leverage cutting-edge technology to produce high-grade TMT bars, ideal for robust construction projects.